When it comes to building materials, there are numerous options available for various construction projects. One popular choice for both residential and commercial applications is split face block. This versatile and aesthetically pleasing material offers unique design possibilities and functional benefits. In this blog post, we will explore what split face block is, its characteristics, and its uses in the construction industry.

The allure of split face block: adding texture to your project

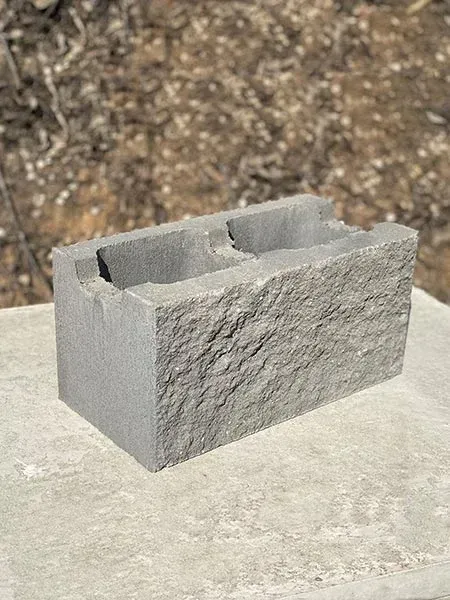

Split face block is a type of concrete masonry unit (CMU) that has a rough, textured face created by splitting the block after it is manufactured. This splitting process exposes the aggregates within the block, resulting in a distinctive and visually appealing appearance. The rough texture of split face block provides an interesting contrast to the smooth surfaces commonly found in traditional concrete blocks or bricks, adding depth and character to any structure.

Commonly used in both interior and exterior applications, split face block offers numerous benefits. Its unique texture can enhance the overall aesthetic of a building, making it an ideal choice for accent walls, fireplaces, and façade treatments. In addition to its visual appeal, split face block also offers excellent durability and weather resistance, making it suitable for outdoor projects such as retaining walls and garden features.

Contact Narellan Sand, Soil & Garden Supplies

If you're looking to enhance the visual appeal and durability of your construction project, consider incorporating

split face block. Its rough texture and versatility make it an excellent choice for both interior and exterior applications. To get started with your project,

contact Narellan Sand, Soil & Garden Supplies, your trusted provider of landscaping supplies. Explore the possibilities of split face block and elevate your construction project to new heights.